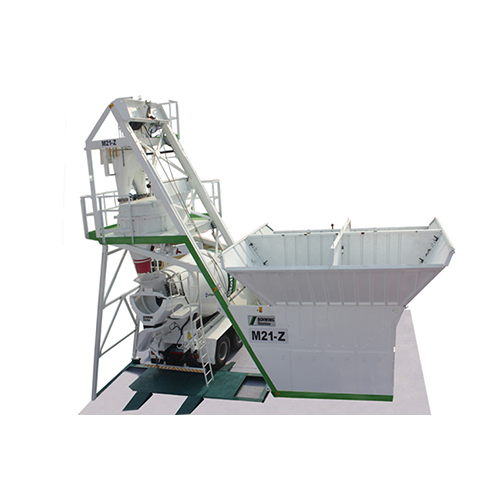

M30Z Mobile Batching Mixing Plant

1400000.00 INR/Unit

Product Details:

- Product Type Batching Plant Spare Parts

- General Use For Batching Plant

- Material Steel

- Type Backhoe Loader Mini Loader

- Capacity 70 m3/hr

- Weight (kg) 1800 Kilograms (kg)

- Computerized Yes

- Click to View more

X

M30Z Mobile Batching Mixing Plant Price And Quantity

- 1400000.00 INR/Unit

- 1 Number

- 700000.00 - 1400000.00 INR/Unit

M30Z Mobile Batching Mixing Plant Product Specifications

- Batching Plant Spare Parts

- 1800 Kilograms (kg)

- Hydraulic Oil Cooling

- 70 m3/hr

- Yes

- For Batching Plant

- Hydraulic Pressure

- Backhoe Loader Mini Loader

- Green

- Steel

- Yes

- 15*3.6*3.5 Meter (m)

- High Quality

- Yes

- PLC Control

- 415 Volt (v)

M30Z Mobile Batching Mixing Plant Trade Information

- 100 Number Per Month

- 7 Days

- STANDERD

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

A Mobile Beaching Plant is a portable and self-contained unit designed to process and manage materials like sand, gravel, and aggregates on or near beaches or coastal areas. These plants are particularly useful for coastal projects such as beach nourishment, erosion control, or construction of coastal infrastructure, where they can quickly be deployed to process materials on-site, minimizing the need for transportation and reducing environmental impact.

Key Features:

- Portability: Mounted on a trailer or wheels, allowing easy transportation and quick setup at various locations.

- Compact Design: The plant is designed to be compact, integrating essential components like hoppers, conveyors, screens, and storage facilities within a limited space.

- Versatility: Capable of handling a variety of materials, from fine sand to larger aggregates, making it suitable for different types of beach projects.

- Efficiency: Equipped with modern processing technology that allows for high throughput, ensuring that large volumes of materials can be processed quickly.

- Environmental Considerations: Designed to minimize environmental impact by reducing dust, noise, and waste materials, making it suitable for sensitive coastal environments.

Applications:

- Beach Nourishment: Adding sand or other materials to eroding beaches to restore their natural state and protect the coastline.

- Coastal Construction: Providing processed materials for the construction of seawalls, jetties, or other coastal infrastructure.

- Dredging Support: Assisting in the processing of dredged materials for reuse or disposal.

Components:

- Hopper: Where raw materials are loaded for initial processing.

- Conveyor System: Transports materials through different stages of processing.

- Screening Unit: Separates materials based on size, ensuring only suitable materials are used.

- Storage Bins: Hold processed materials before they are transported or used on-site.

Advantages:

- Flexibility: Can be moved to different locations as needed, reducing logistics costs.

- Cost-Effective: Reduces the need for transporting raw materials to off-site processing plants.

- Rapid Deployment: Can be quickly set up and operational in a short amount of time, crucial for emergency beach repair or maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS