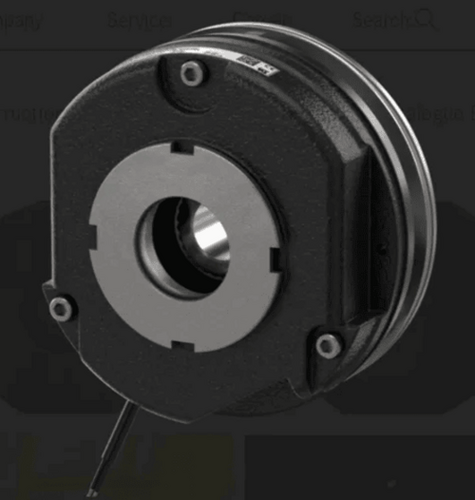

intorq BKF 459

3000.00 - 6000.00 INR/Number

Product Details:

- Length 6 Inch (in)

- Weight 2 Kilograms (kg)

- Color BLACK

- Height 6 Inch (in)

- Size 0.8

- Product Type INDUSTRIAL BRAKE

- Width 5 Inch (in)

- Click to View more

X

intorq BKF 459 Price And Quantity

- 3000.00 - 6000.00 INR/Number

- 1 Number

intorq BKF 459 Product Specifications

- 130 Millimeter (mm)

- 8 Watt (w)

- BRAKING SYSTEM

- Brake motors

- 180 Volt (v)

- 0.8

- INDUSTRIAL BRAKE

- Cast iron or high-grade steel

- 5 Inch (in)

- 6 Inch (in)

- BLACK

- 6 Inch (in)

- 2 Kilograms (kg)

intorq BKF 459 Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Cheque Telegraphic Transfer (T/T)

- 100 Number Per Day

- 3 Days

- STANDARD

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Intorq's industrial brakes, including models like the Intorq BFK459, are known for their reliability, durability, and adaptability to various industrial applications. Here are the key features that make Intorqïs industrial brakes stand out:

1. Spring-Applied Fail-Safe Design

- Fail-Safe Operation: Intorq brakes engage automatically when the power is cut off, making them inherently safe for emergency stops or "In the event that" power failures.

- Spring-Applied Mechanism: These brakes are applied using spring force and released electromagnetically, providing precise and reliable braking control.

2. Modular and Customizable Design

- Modular Construction: Intorq brakes are designed in a modular fashion, which allows easy customization to fit specific applications. This makes it possible to adjust components such as friction linings, hubs, and release mechanisms.

- Interchangeable Components: Components can be easily replaced or adapted, reducing maintenance costs and increasing flexibility.

3. Wide Torque Range

- Torque Capacity: Intorq brakes cover a wide torque range, typically from 1.5 Nm to 600 Nm, making them suitable for applications from small automation systems to heavy-duty industrial machinery.

- Versatility: This wide range allows the brakes to be used in a variety of industries, from automation and robotics to heavy equipment and wind turbines.

4. Low Maintenance and Long Service Life

- Durable Materials: Built from high-quality, wear-resistant materials, Intorq brakes are designed for a long operational life, even under harsh conditions.

- Minimal Maintenance: The brakes require minimal maintenance, reducing downtime and increasing overall operational efficiency.

5. Quiet Operation

- Low Noise Levels: Intorq brakes are engineered for quiet operation, even in high-cycling environments. This is crucial for applications in areas where noise reduction is a priority, such as in automated warehouses or assembly lines.

6. Energy Efficiency

- Low Power Consumption: When releasing the brake, the power consumption is minimal, contributing to energy savings in continuous or frequent use applications.

- Optimized Design: The electromagnetic release mechanism is designed to be efficient, ensuring minimal power use during release and safe engagement during operation.

7. Fast Response Time

- Quick Engagement/Release: The brakes are designed for fast switching times, ensuring rapid engagement and disengagement, which is critical for precision applications like material handling systems or robotics.

- Reliable Performance: Quick response times enhance safety and performance, especially in stop-start operations.

8. Manual Release Options

- Manual Override: Many Intorq brakes feature a manual release mechanism, allowing the brake to be disengaged in the event of power failure or during maintenance.

- Emergency Handling: This feature is particularly useful in emergencies, where machinery may need to be moved manually.

9. Temperature Resistance

- Wide Operating Temperature Range: Intorq brakes are designed to operate in a broad temperature range, typically from -20C to +40C, ensuring reliable performance in both cold and hot environments.

10. IP Protection Ratings

- Protection Against Dust and Water: Intorq brakes are available with protection ratings up to IP66, making them suitable for use in harsh environments with exposure to dust, dirt, and water.

- Corrosion Resistance: For outdoor or highly corrosive environments, the brakes can be made with special coatings to ensure longevity.

11. Compact Design

- Space-Saving Construction: Despite their powerful torque capacities, Intorq brakes are compact, allowing for easy integration into machines with limited space.

- Flexible Mounting: They can be mounted in various orientations, making them adaptable to different machine configurations.

12. Compliance with Industry Standards

- Certified Safety and Quality: Intorq industrial brakes are built to meet various industry standards, including CE and ISO certifications, ensuring high quality and safety in critical applications.

13. Versatile Application

- Industry Use: Intorq brakes are used in a wide range of industries, including:

- Material handling

- Robotics and automation

- Wind turbines

- Conveyor systems

- Machine tools

- Elevators and escalators

Enter Buying Requirement Details

Send Inquiry

Send Inquiry Send SMS

Send SMS