Horizontal Batching Plant Spare Parts

Product Details:

- Product Type Batching Plant Spare Parts

- General Use Construction

- Material Steel

- Type Backhoe Loader Front Loader Mini Loader Cement Mixer Construction Hoist Excavator

- Capacity 150 m3/hr

- Weight (kg) 3125 Kilograms (kg)

- Computerized Yes

- Click to View more

Horizontal Batching Plant Spare Parts Price And Quantity

- 1 Number

- 4500000.00 INR/Unit

Horizontal Batching Plant Spare Parts Product Specifications

- Construction

- 6 month

- Yes

- Hydraulic Pressure

- PLC Control

- Steel

- 150 m3/hr

- Backhoe Loader Front Loader Mini Loader Cement Mixer Construction Hoist Excavator

- Batching Plant Spare Parts

- Customized

- Hydraulic Oil Cooling

- 415 Volt (v)

- High Quality

- 3125 Kilograms (kg)

- Yes

- 1600*1400*2900 Centimeter (cm)

Horizontal Batching Plant Spare Parts Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID)

- 1 Number Per Month

- 30 Days

- standard

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

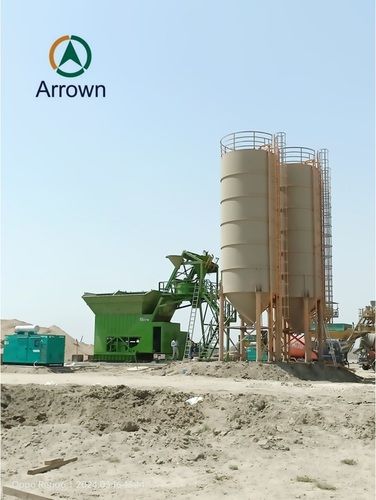

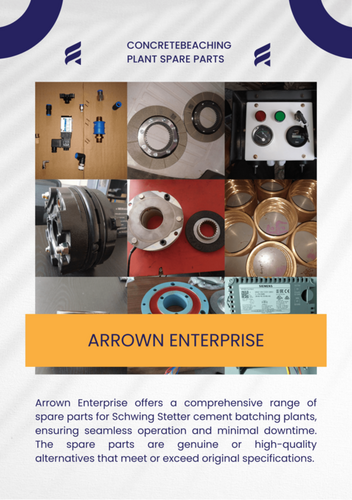

Arrown Enterprise is known for providing a range of spare parts and components for concrete batching plants, including horizontal batching plants like those used in the construction industry. While the specific parts may vary based on the plant model and configuration, here are some of the common spare parts and components that Arrown Enterprise typically supplies:

Common Spare Parts Provided by Arrown Enterprise for Horizontal Batching Plants:

-

Mixer Components:

- Mixing Arms and Blades: High-quality wear-resistant mixing arms and blades for twin-shaft and planetary mixers.

- Mixer Liners: Replaceable liners that protect the inside of the mixer drum.

- Shaft Seals and Bearings: Essential for the smooth operation of the mixer, preventing leaks and wear.

- End Seals: To prevent material leakage from the ends of the mixer shaft.

-

Conveyor and Belt System:

- Conveyor Belts: Durable belts for aggregate and cement transportation, available in various sizes.

- Rollers and Idlers: Support rollers and idlers for conveyor belts, ensuring smooth operation.

- Belt Scrapers: Used to clean the conveyor belts, preventing material buildup.

- Bearings: High-quality bearings for conveyor systems.

-

Aggregate Handling System:

- Aggregate Bins: Replacement parts for aggregate storage bins, including liners and gates.

- Pneumatic Cylinders: Used for operating aggregate bin gates and discharge systems.

- Bin Vibrators: To ensure smooth flow of aggregates and prevent blockages.

-

Weighing System Components:

- Load Cells: Accurate load cells for weighing aggregates, cement, and water.

- Weighing Hoppers: Replacement hoppers for aggregates and cement.

- Water Flow Meters: Precision flow meters for accurate water dosing.

- Additive Dosing Systems: Components for precise dosing of chemical additives.

-

Cement Silo and Feeding System:

- Screw Conveyors: For efficient cement transfer from silos to the batching plant.

- Silo Filters: Dust collectors and filters for cement silos.

- Pressure Relief Valves: Safety valves for releasing excess pressure in silos.

- Butterfly Valves and Slide Gates: For controlling the flow of cement from the silos.

-

Hydraulic System Parts:

- Hydraulic Pumps: For operating gates, mixers, and other hydraulic components.

- Hydraulic Cylinders: Replacement cylinders for moving gates and other components.

- Hydraulic Hoses and Fittings: Essential for the hydraulic system, ensuring leak-free operation.

- Hydraulic Filters: To keep the hydraulic fluid clean and prevent contamination.

-

Control System and Electrical Components:

- PLC Modules: Programmable Logic Controllers for the automated batching plant control system.

- HMI (Human-Machine Interface): Touchscreen interfaces for controlling plant operations.

- Sensors and Switches: Various sensors for monitoring plant performance and ensuring safety.

- Cables and Connectors: Electrical wiring and connectors for the control system.

-

Discharge and Hopper Components:

- Discharge Gates: Replacement gates for controlling concrete flow from the mixer.

- Hopper Liners: Wear-resistant liners for concrete hoppers.

- Discharge Chutes: Chutes for directing the flow of concrete during discharge.

-

Miscellaneous Parts:

- Seals and Gaskets: For preventing leaks and ensuring tight seals in various components.

- Bolts and Fasteners: High-strength fasteners for securing components.

- Lubrication Systems: For maintaining proper lubrication of moving parts.

- Safety Equipment: Emergency stops, alarms, and guards to ensure safe operation.

Why Choose Arrown Enterprise for Spare Parts:

- Quality Assurance: Arrown Enterprise is known for supplying high-quality, durable parts that meet or exceed industry standards.

- Wide Range: They offer a comprehensive range of parts suitable for various makes and models of horizontal batching plants.

- Customer Support: Arrown Enterprise provides excellent customer service, including technical support and assistance in selecting the right parts.

For specific parts, prices, or availability, it's best to contact Arrown Enterprise directly, as they can provide tailored solutions based on the exact model and configuration of your batching plan

Send Inquiry

Send Inquiry Send SMS

Send SMS